8mm carbon crystal plate

Carbon crystal plates, with their excellent physical properties, diverse functions, wide range of application scenarios and environmental protection features, are gradually replacing traditional materials in the fields of construction, home furnishing and industry. Its core advantages can be summarized as "high strength, light weight, high temperature resistance, easy installation and long service life". In the future, with technological progress, the cost is expected to further decrease and the application scenarios will continue to expand.

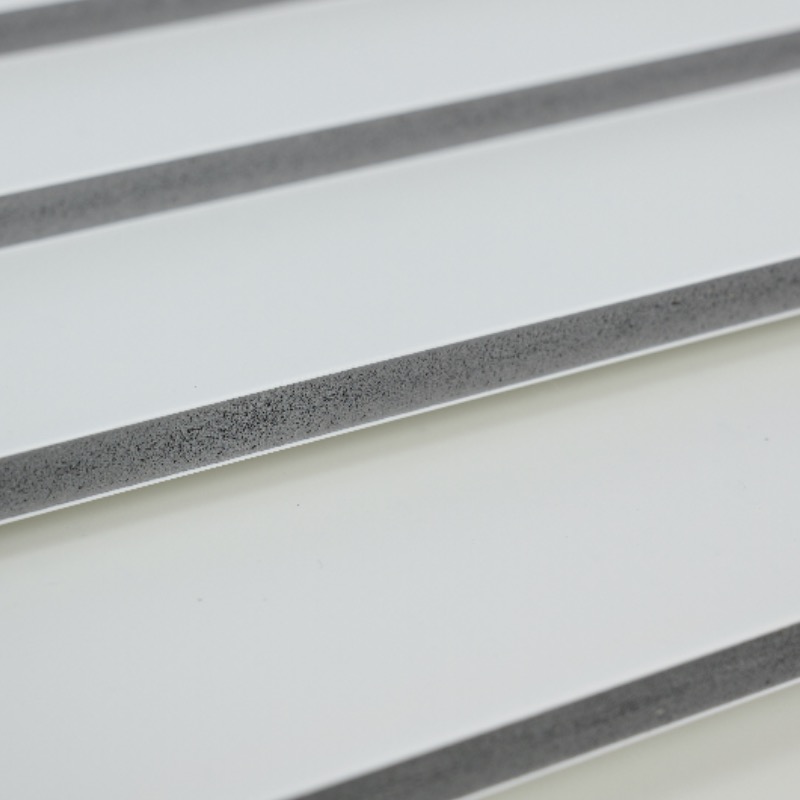

Details

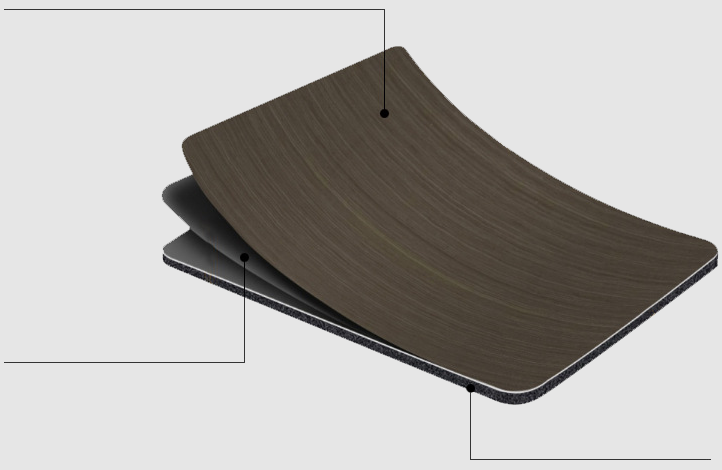

Upgraded version

Carbon crystal fiber solid core large board

——

·

Innovative introduction of arch extrusion process

The substrate surface and inner core are produced separately and integrated according to different standards

Better reinforcement of the surface and inner core for different performance requirements

Wear-resistant PVC film paper

Clear texture and delicate feel

Bonding layer

Imported PUR hot melt adhesive

Green and no smell

High density substrate

It is not easy to deform under press

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

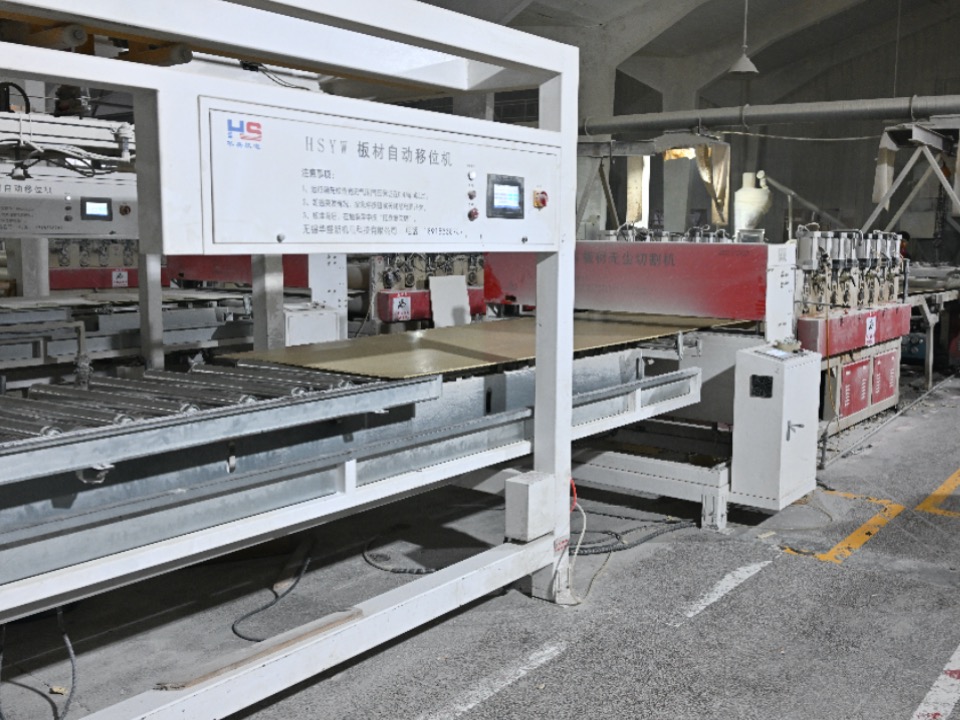

Factory real show

Focus on production quality assurance

Carbon crystal plate is a new type of plate made of carbon element crystals and has demonstrated significant advantages in multiple fields. The following is a detailed explanation from different dimensions:

I. Physical performance advantages

High strength and high hardness

The internal carbon crystal structure of the carbon crystal plate is compact, with a hardness of 6-7 on the Mohs scale (close to that of quartz). It has strong impact resistance and is not prone to depression or breakage due to external force impact. It is suitable for scenarios such as furniture and architectural decoration that require wear and tear resistance.

For instance, when used as a floor material, it can withstand the long-term pressure of heavy objects without deforming.

Lightweight and environmentally friendly

The density is usually 1.5-2.0g/cm³, slightly heavier than traditional wood (about 0.6-1.0g/cm³), but much lower than that of metal plates (such as steel plates 7.8g/cm³), which is convenient for transportation and installation.

No harmful substances such as formaldehyde and benzene are added during the production process, meeting environmental protection standards (such as E0 grade). It is often used in interior decoration to reduce air pollution.

High-temperature resistance and fire resistance

The melting point can reach over 3000℃. It is not easy to burn when exposed to open flames and only carbonizes. It belongs to B1 grade fireproof material (difficult-to-burn material) and can reduce the risk of fire in the construction field.

For instance, when used as a wall decorative panel, it can effectively block heat transfer and delay the spread of fire.

Ii. Functional Characteristic Advantages

Efficient heat conduction and dissipation

The thermal conductivity can reach 200-400W/(m · K), nearly twice that of metallic aluminum (237W/(m · K)). It is often used in heating equipment (such as carbon crystal floor heating panels), with a fast heating speed (reaching the preset temperature within 15-30 minutes) and uniform heat distribution.

It has low energy loss during heat dissipation and remarkable energy-saving effect, saving about 30% energy compared with traditional electric heating film floor heating.

Corrosion-resistant and anti-aging

It has stable chemical properties and is resistant to corrosion from acids, alkalis, salts, etc. It is not prone to mold or rust in damp and highly acidic or alkaline environments (such as bathrooms and laboratories), and its service life can reach 10 to 15 years (about 5 to 8 years for traditional wooden boards).

It has strong UV resistance and is not prone to fading or cracking when exposed outdoors for a long time, making it suitable for outdoor decoration.

Electromagnetic shielding and anti-static

Carbon crystal materials have excellent electrical conductivity and can form an electromagnetic shielding layer, reducing the radiation interference from electronic devices such as computers and routers. They are often used in places with high requirements for the electromagnetic environment, such as computer rooms and hospitals.

It has a low surface resistance (10⁴-10⁶Ω), is not prone to accumulate static electricity, and avoids the influence of dust adhesion and static discharge on precision instruments.

Iii. Application Scenario Advantages

The field of architectural decoration

Wall/floor decoration: It can replace tiles and wood, has waterproof and moisture-proof properties, no additional waterproof treatment is required, is easy to install (modular splicing), and saves construction time.

Energy conservation and insulation: When used as a building insulation layer, it has a low thermal conductivity (0.02-0.04W/(m · K)), which is more efficient than traditional insulation materials (such as polystyrene board 0.041W/(m · K)), reducing the energy consumption of buildings.

The field of home furnishings and furniture

Furniture making: The surface of the board is smooth and can be directly sprayed or veneered. It comes in various shapes (such as custom wardrobes and coffee tables), and is lightweight, making it easy to move and install.

Kitchenware: Heat-resistant, easy to clean, can be used to make cabinet panels. Grease stains can be wiped off with a simple wipe, avoiding the problem of traditional boards swelling when exposed to water.

The field of industry and technology

Heat dissipation for electronic devices: It is used to manufacture CPU heat sinks and heat dissipation substrates for LED lamps, quickly dissipating heat and extending the lifespan of the devices.

In the field of new energy: As a carrier for the anode material of lithium batteries or a conductive substrate for solar panels, it enhances the efficiency of energy conversion.

Iv. Advantages in Installation and Maintenance

Easy to install

The specifications of the slabs are uniform (such as 1220mm×2440mm), and they can be cut and drilled as needed. They are fixed by snap-fit or screws, without the need for professional tools. The construction efficiency is more than 50% higher than that of traditional stone.

Low maintenance cost

The surface wear-resistant layer can resist daily scratches. Stains can be wiped directly with a damp cloth without the need for regular waxing or painting. The maintenance cost is about 40% lower than that of wooden boards.

V. Environmental Protection and Sustainability Advantages

The material is recyclable.

Waste carbon crystal plates can be recycled through physical crushing or chemical treatment, reducing solid waste pollution and conforming to the concept of a circular economy.

Low-carbon production

The energy consumption in the production process mainly comes from high-temperature sintering (accounting for about 60% of the total energy consumption), but compared with traditional building materials such as steel and cement, carbon emissions are reduced by about 30%, and fossil fuels can be replaced by renewable energy sources (such as electricity).

Summary

Carbon crystal plates, with their excellent physical properties, diverse functions, wide range of application scenarios and environmental protection features, are gradually replacing traditional materials in the fields of construction, home furnishing and industry. Its core advantages can be summarized as "high strength, light weight, high temperature resistance, easy installation and long service life". In the future, with technological progress, the cost is expected to further decrease and the application scenarios will continue to expand.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)