Metal film carbon crystal plate

PVC metal film carbon crystal plate is a new type of decorative material.

It is mainly composed of bamboo charcoal powder, calcium powder, PVC and additives, etc. Through high-temperature melting, co-extrusion of the surface core layer, cooling treatment and other processes, the base material is formed in one piece. This co-extruded sheet has hard PVC layers on both the upper and lower sides, and a unique honeycomb-like hexagonal molecular structure formed by the blending of bamboo charcoal powder, resin and high molecular materials at high temperatures in the middle, which gives it certain strength and stability.

Details

Upgraded version

Carbon crystal fiber solid core large board

——

·

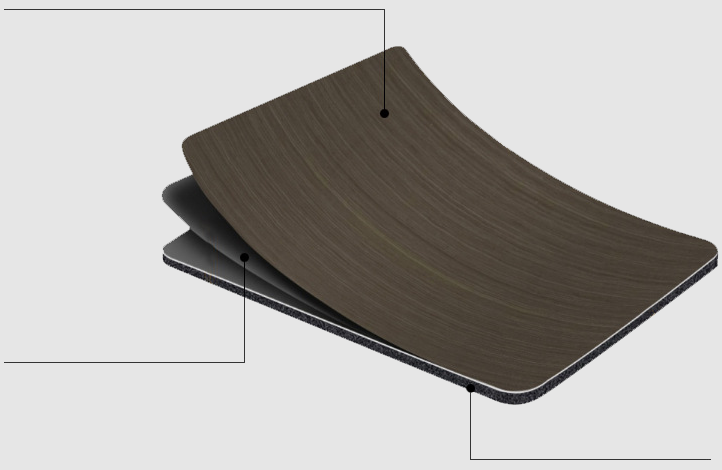

Innovative introduction of arch extrusion process

The substrate surface and inner core are produced separately and integrated according to different standards

Better reinforcement of the surface and inner core for different performance requirements

Wear-resistant PVC film paper

Clear texture and delicate feel

Bonding layer

Imported PUR hot melt adhesive

Green and no smell

High density substrate

It is not easy to deform under press

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

Activated carbon powder formula

Decomposition of formaldehyde and other harmful gases

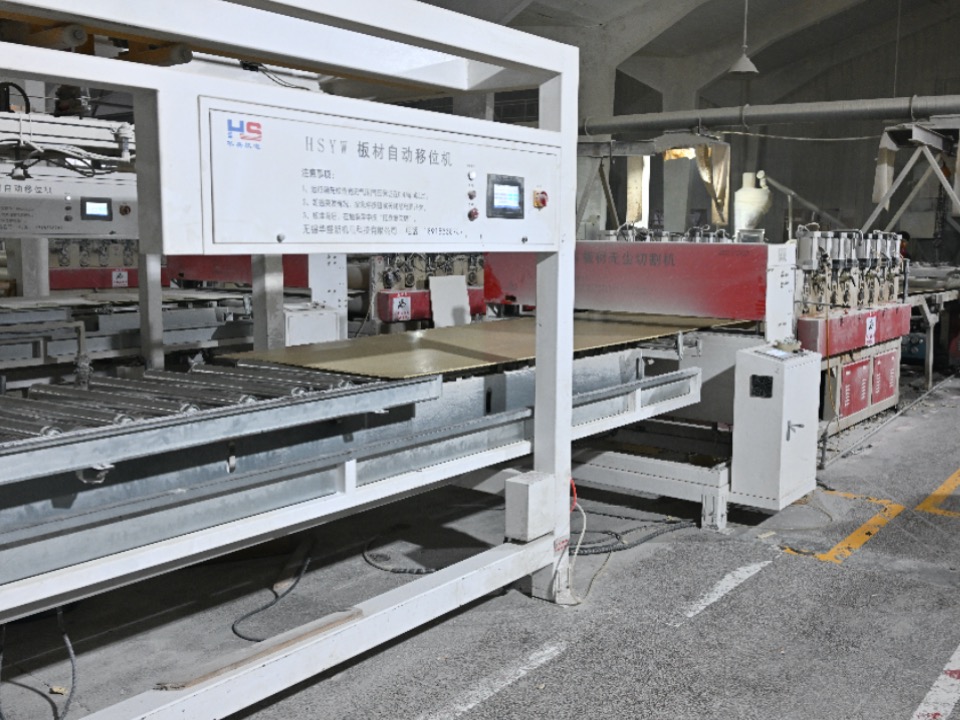

Factory real show

Focus on production quality assurance

PVC metal film carbon crystal plate is a new type of decorative material. The following is a detailed introduction about it:

1.Material composition

Carbon crystal plate base material: It is mainly composed of bamboo charcoal powder, calcium powder, PVC and additives, etc. Through high-temperature melting, co-extrusion of the surface core layer, cooling treatment and other processes, the base material is formed in one piece. This co-extruded sheet has hard PVC layers on both the upper and lower sides, and a unique honeycomb-like hexagonal molecular structure formed by the blending of bamboo charcoal powder, resin and high molecular materials at high temperatures in the middle, which gives it certain strength and stability.

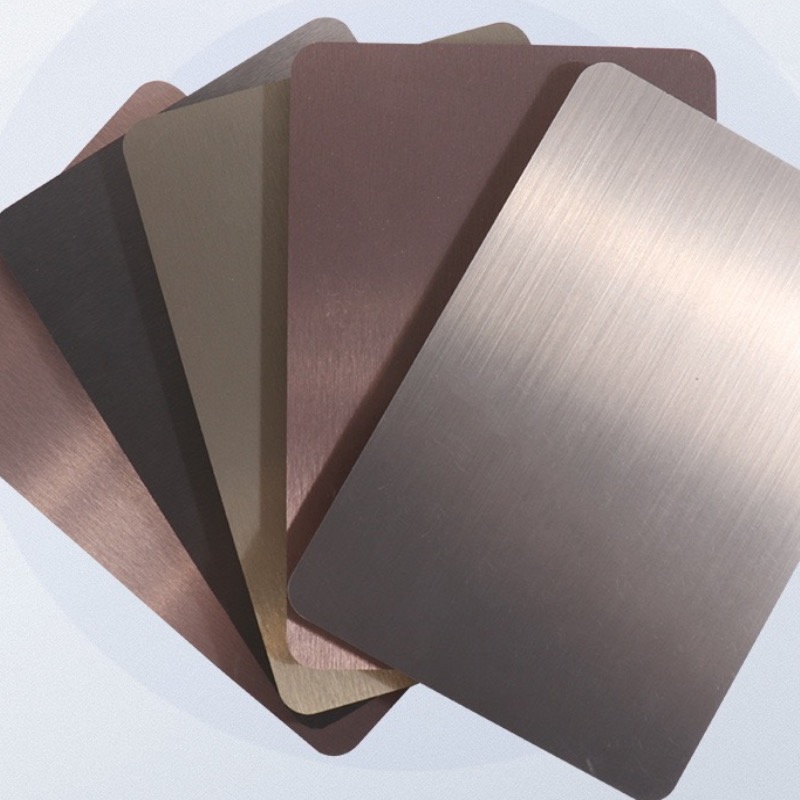

PVC metal film: Through the PUR hot melt adhesive process or other lamination techniques, a PVC film with a metallic texture is coated on the surface of the carbon crystal board substrate. PVC metal film can present various metallic effects, such as metal brushing and mirror finish, adding a unique decorative touch to the sheet.

2. Performance characteristics

Strong decorative effect: PVC metal film features a rich variety of patterns and textures, such as brushed metal, mirror finish, copper imitation, and aluminum imitation, which can create a modern, fashionable, and luxurious decorative atmosphere. It can meet the design requirements of different Spaces and styles, such as wall and background wall decoration in commercial places, hotels, and homes.

Waterproof and moisture-proof: The raw materials of carbon crystal board, such as PVC resin, calcium powder, and carbon powder, have the property of not absorbing water. Coupled with the PVC metal film on the surface, which serves as a seal, water vapor is difficult to enter the interior of the board, effectively preventing wall mold and moisture. It is suitable for environments with high humidity, such as bathrooms, kitchens, and basements.

Wear-resistant and scratch-resistant: The carbon crystal plate itself has a relatively high hardness, and the PVC metal film on its surface has also undergone special treatment, providing excellent wear resistance and scratch resistance. It is not easily scratched or worn, and can maintain a smooth and beautiful surface for a long time. Even after years of use, it can still maintain a good texture.

Environmental protection and health: The core material is prepared through the PVC co-extrusion process without using aldehyde-containing adhesives, achieving no formaldehyde addition and meeting national environmental protection standards. This reduces the release of harmful substances such as formaldehyde during the decoration process, making it more friendly to human health and the environment.

Easy installation: Compared with traditional wood veneer, its customization cycle is shorter, generally around 3 to 7 days. The height and width can be freely cut and adjusted. It can be slotted and bent on site, and used to wrap corners and columns, achieving various unique shapes. The installation methods are mostly panel structure, modular installation, fast construction speed, and can effectively shorten the decoration period.

3. Application fields

Home decoration: It can be used for wall decoration in living rooms, bedrooms, studies and other rooms to create distinctive background walls. It can also be used on the walls of kitchens and bathrooms, replacing traditional tiles, and has the advantages of being waterproof and easy to clean. It can also be used as a partition material, dividing the space while serving a decorative function.

Commercial space: Widely used in the decoration of commercial places such as shopping malls, hotels, restaurants, KTVS, and bars, such as wall decoration, background wall creation, and display stand production, it can enhance the grade and atmosphere of the space and attract customers.

Public buildings: In public buildings such as hospitals, schools, office buildings and stations, it can be used for decoration of walls, corridors, halls and other parts. It has the characteristics of fire resistance, environmental protection and easy cleaning, and meets the usage requirements of public buildings.

Why choose Haohai? Haohai has many years of production experience, strict quality inspection control, better equipment and better quality.

1.Factory direct sales, tailor-made

We customize solutions based on customer needs, focus on the industry for over 20 years, and produce various products to meet your demands. Continuous technological innovation has accumulated a number of unique production processes and a professional and efficient R&D technical team. With 40 technicians, we are well-prepared to meet your OEM/ODM needs and your customized requirements.

2. Highly praised and cost-effective

The company has strong technical force and advanced production equipment, as well as high-quality products and favorable prices. Introduce professional production equipment, improve product quality, strictly control quality and ensure reliable quality. With over 6,000 cooperative clients and services provided to numerous enterprise customers, it is trustworthy.

3. Considerate service and after-sales guarantee

The company has been specializing in the decoration materials industry for many years, possessing a core development team and rich industry service experience, etc. We focus on sales solutions and technical services 365*8 hours a day. Our after-sales service responds quickly, saving you time, effort and worry.

Haohai New Materials Customization Process

Professional PVC extrusion customization process, meticulous service for every step

1.Demand communication

Understand the detailed re-quirements of the product

2.Product Quotation

Make reasonable quotations based on the products

3、Mold opening and sample making

Make molds and samples ac-cording to the drawings or samples

4.Confirm the sample

Confirm the profile samples and pay the full amount

5.Production inspection

After production is complet- ed, inspect the quality

6.Delivery and after-sales service

The seller ships the goods and tracks the logistics infor-mation

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)