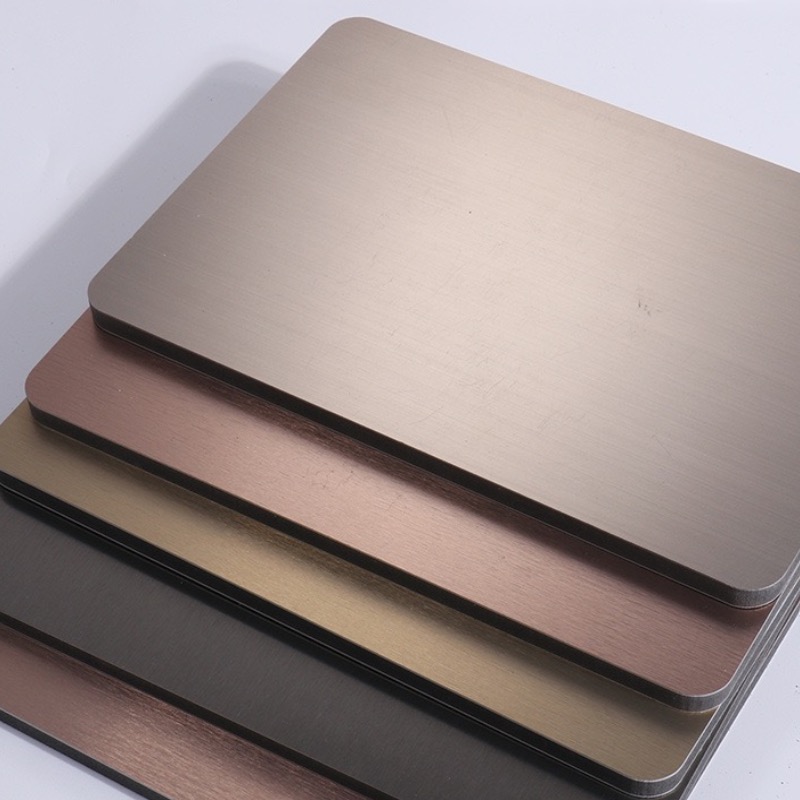

Metalized wood veneer

PVC metal film wall panels are decorative boards with PVC as the base material and a metal-textured film layer on the surface. They combine the modern metallic luster with the practical performance of PVC materials, making them an ideal choice for commercial Spaces and modern homes.

Details

Product advantage

/ / /

Bacteria and moisture proof

Sound absorption and sound insulation

Double-sided fire protection

Quality assurance

Stable performance

durable

Product details display

/ / /

You need a product that works so well

All-round display

Let you better understand our products

01

Bacteria and moisture proof

Can be used for water testing surface wear resistance and corrosion resistance

02

Green and environmental protection

Made of special substrate, good fire and water insulation, safe to use, suitable for different scenarios

03

Thickened sheet

Real material, imported logs are tough and light, with a clear grain

04

Class B fire protection

No asbestos, does not contain radioactive elements, suitable for the national fire requirements of public places

Product shooting

/ / /

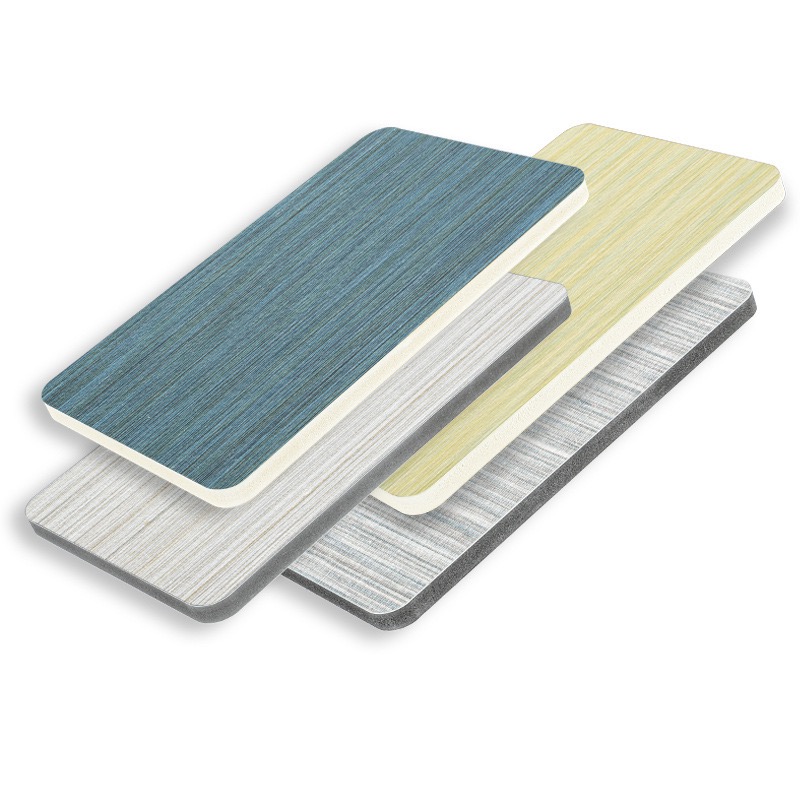

You can choose from a variety of styles

All-round display

Let you better understand our products

Product specifications

Support customization

Price unit

square meter

Product features

fireproof, moisture-proof, antibacterial

Product color

multi-color optional

Scope of application

hospitals, shopping malls, hotels, office areas, entertainment venues

Application scenario

/ / /

Widely used in underground tunnels, subways, hospitals, municipal construction and other fields, suitable for residential, shopping malls, office buildings, hotels, hotels, entertainment places on fire, environmental protection, moisture, mildew and other high requirements of indoor decoration.

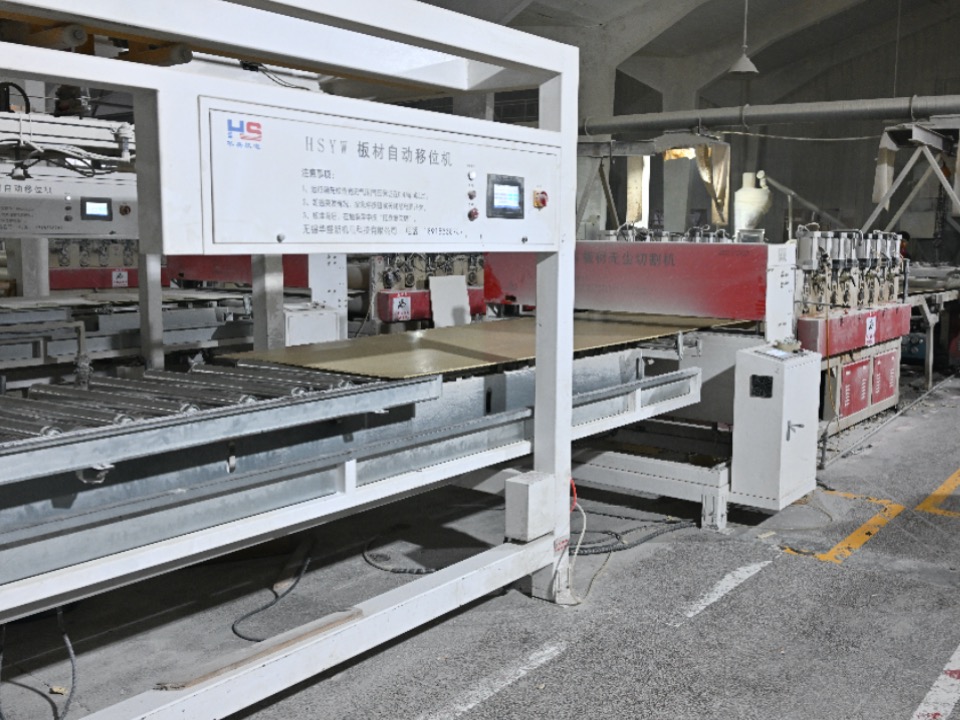

Factory real show

Focus on production quality assurance

PVC metal film wall panels are decorative boards with PVC as the base material and a metal-textured film layer on the surface. They combine the modern metallic luster with the practical performance of PVC materials, making them an ideal choice for commercial Spaces and modern homes.

1.Core features of the product

(1) Decorative

Metallic texture:The surface presents effects such as brushed, mirror finish, matte finish, and titanium plating, enhancing the technological feel and light luxury atmosphere of the space.

Rich in colors: Customizable popular metallic colors such as gold, silver, copper, black titanium, and rose gold are available.

Diverse textures: Pure metal surfaces are available, or combined with wood grain, stone grain, and geometric patterns for design.

(2) Functionality

Waterproof and moisture-proof: 100% waterproof, suitable for damp areas such as bathrooms, kitchens, and basements.

Wear-resistant and scratch-resistant: The surface is treated with UV coating, and its scratch resistance is superior to that of ordinary paints or wallpapers.

Lightweight and high strength: The PVC base material is light in weight but has good impact resistance and is not prone to deformation.

Environmental protection and safety: Free of formaldehyde (E0/ENF grade), and has passed international certifications such as SGS and CE.

Sound insulation and heat insulation: Some hollow structure designs can enhance the sound insulation and heat insulation effects.

(3) Easy to install

Snap-fit installation: No complex tools are required, and it can be directly spliced, saving working hours. Adhesive bonding or nailing: Suitable for different base layers (walls, ceilings, furniture veneers).

2. Applicable scenarios:

Home decoration: TV background wall, kitchen splash guard, bathroom wall, balcony ceiling

Commercial Spaces: hotel lobbies, office partitions, display cabinets in shopping malls, and walls of brand specialty stores

Industrial style design: Wall and furniture finishes in cafes, bars, and LOFT Spaces

Special requirements: Moisture-proof for laboratories, hospitals (antibacterial type), and basements

Haohai New Materials Customization Process

Professional PVC extrusion customization process, meticulous service for every step

1.Demand communication

Understand the detailed re-quirements of the product

2.Product Quotation

Make reasonable quotations based on the products

3、Mold opening and sample making

Make molds and samples ac-cording to the drawings or samples

4.Confirm the sample

Confirm the profile samples and pay the full amount

5.Production inspection

After production is complet- ed, inspect the quality

6.Delivery and after-sales service

The seller ships the goods and tracks the logistics infor-mation

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)